Make your own practice or contest maze

Full size maze

Floor Panels

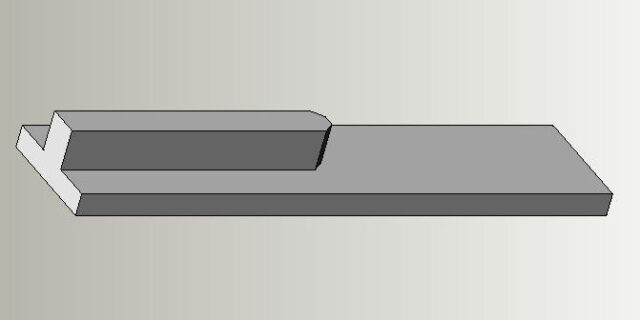

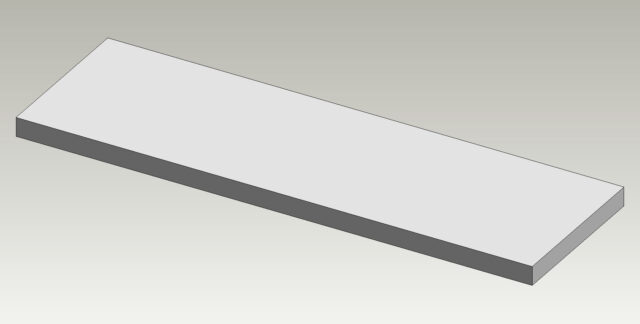

All maze panels are identical and are typically made from 12mm MDF. A tongue and groove arrangement on the top and right edge serves to align adjacent panels with a minimum risk of steps or gaps.

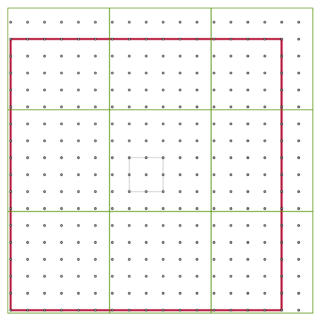

Each is 1080mm square with the post holes 10mm from the left and bottom edges, and 170mm from the top and right edges.

The size is chosen for maximum flexibility while still making it easy to transport in a typical family car.

A 1220mm x 2440mm sheet contains enough material to make two panels and 48 walls with care. Note that 48 walls is not really enough for a 5×11 maze. 75 walls would be a better number.

Holes for the posts are 6.1mm diameter on 180mm centres.

Each panel can be used to make a 5×5 practice maze.

When nine panels are combined for a contest, there is a one-cell additional boundary that can be used for sensor calibration.

A minimum of three panels is needed to create a maze with a ‘legal’ goal area.

Four panels combined will make a 11×11 mini-maze for occasional events.

The construction of these floor panels was given at Minos 2018.

The panels used for the half-size maze are the same as those used for a full-size maze as described by Duncan Louttit and Bernard Grabowski at the 2018 Minos conference. You can find the descriptions here:

Half size maze

Floor Panels

The maze base is made from 12mm MDF routed to size and with the holes drilled using a CNC router. If you need this done, email UKMARS@swallow.co.uk and we will try and arrange it. They cost £40 per pair for collection from Stroud. This can be used on its own for mazes up to 10 by 10 or with a tongue and groove arrangement similar to the full-size maze to allow them to be extended to any desired size.

The panels used for the half-size maze are similar to those used for a full-size maze as described by Duncan Louttit and Bernard Grabowski at the 2018 Minos conference.

The difference is in the panel size and hole spacing.

Each panel is 900mm square with a grid of 6.1mm post holes on 90mm centres, starting 10mm from the left and bottom edge

Walls and Posts

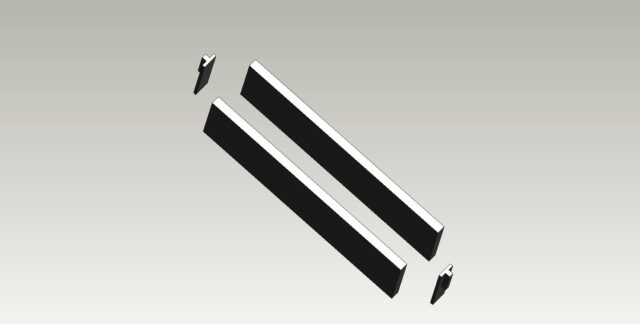

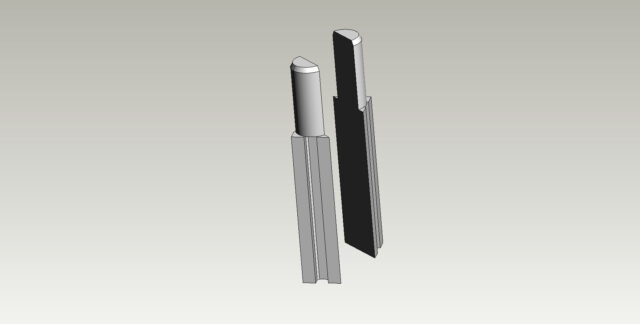

The walls are 3D printed in ABS in four pieces. There are two identical thin wall sections that are glued together with acetone. This means that the outsides are the face that is printed on the bed of the printer for best finish.

These parts will need fettling on a piece of fine sandpaper to avoid printing flash etc.

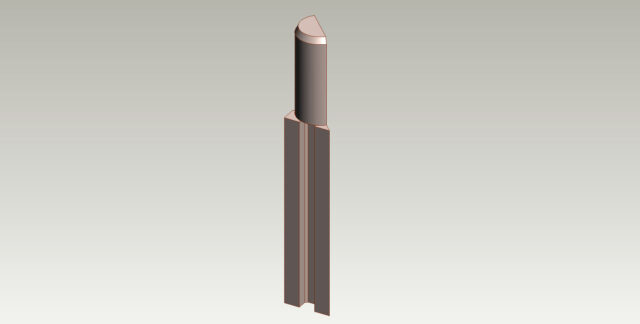

The posts are 3D printed in ABS as two pieces glued together with acetone. They are printed flat-side down on the bed. This ensures that the layers are in the correct orientation for strength.

These parts will need fettling with a swiss file to remove printer artefacts as needed.

The prototypes were printed in TitanX white ABS on a Robox printer.

STL files for each of these components can be found at: